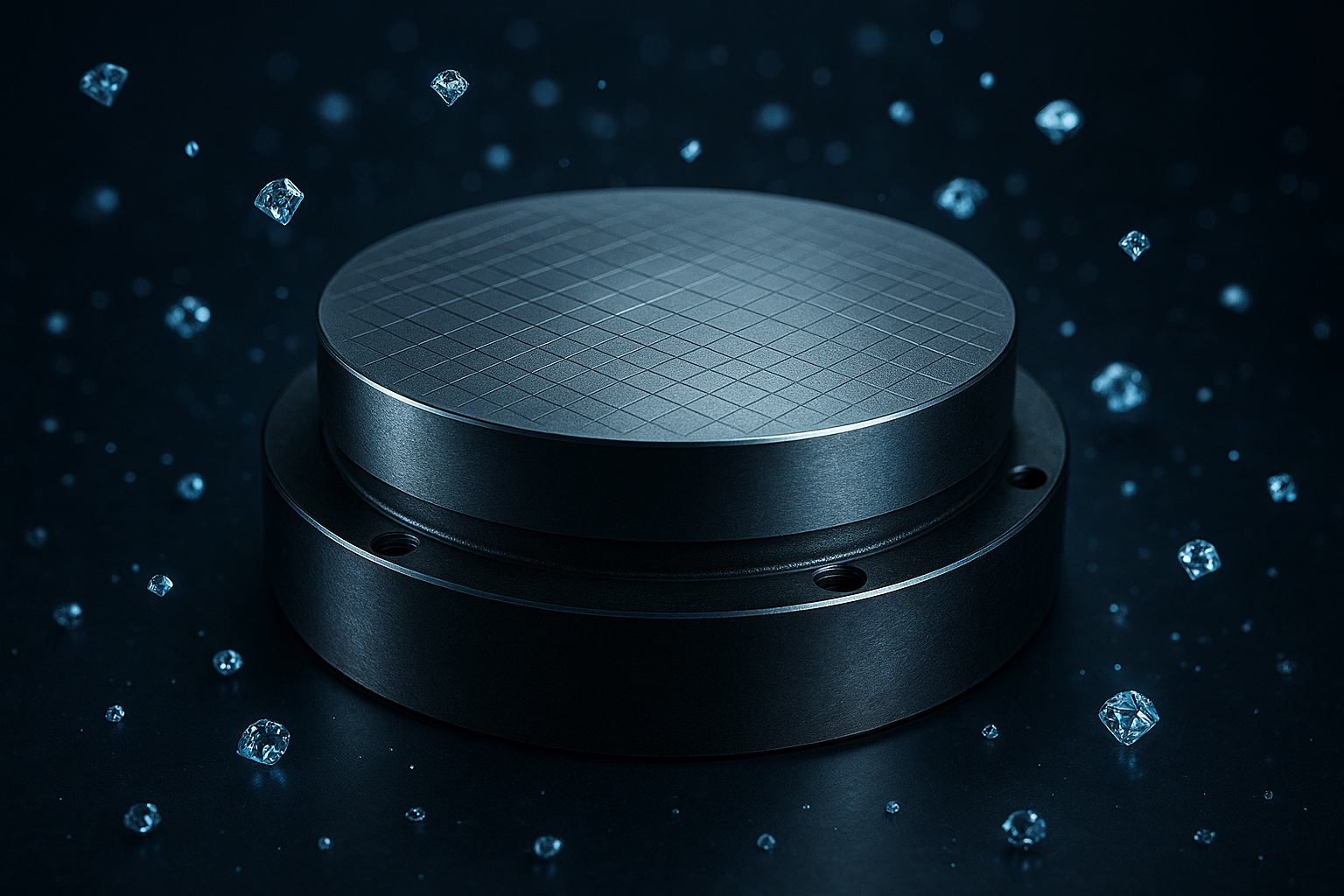

Technology That Redefines Industrial Protection

Smarter Than Steel. More Resilient than Chrome. Powered by Nano-Diamonds.

At the heart of Metal Diamond lies a breakthrough in materials science that is not just revolutionary—it is protected, patented, and exclusive. Our Electroless Nickel Nano-Diamond (EN-ND) composite coating is more than a surface treatment; it is the world’s first industrialized fusion of functionalized nanodiamonds with a nickel-phosphorous matrix.

The result? A technology that transforms ordinary steel into a super-material—harder, stronger, longer-lasting, and more intelligent than anything else on the market.