Oil & Gas Coatings — Electroless Nickel Nano-Diamond for Extreme Environments

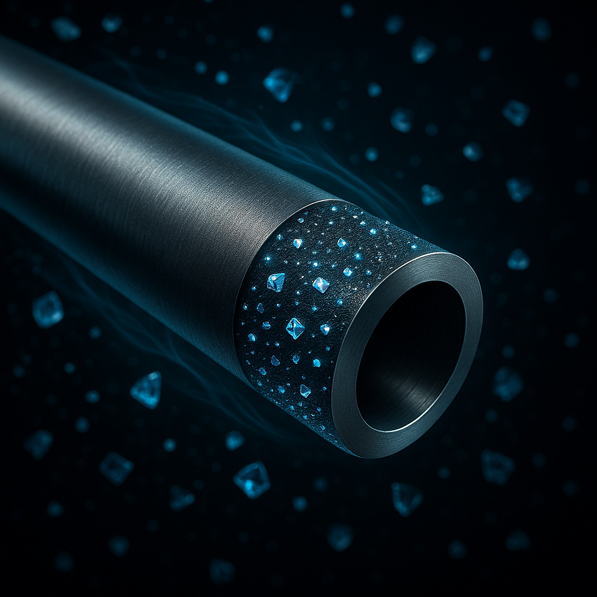

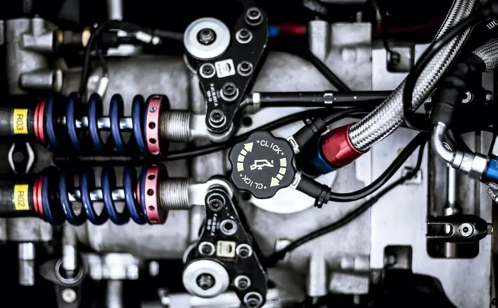

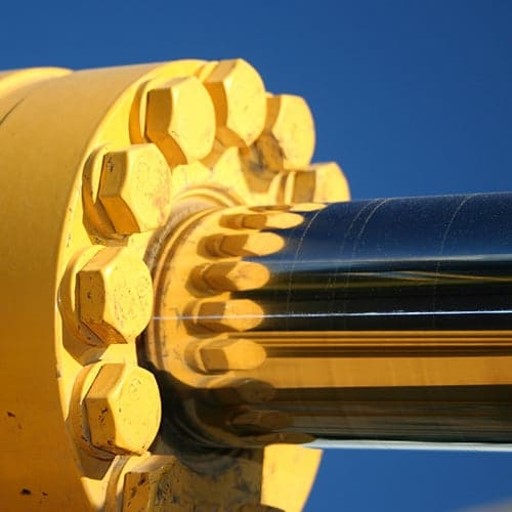

When wells run hot, sour, and sand cut, downtime is the most expensive line item on the balance sheet. Metal Diamond's Electroless Nickel Nano Diamond coating (EN ND) is engineered to protect critical oilfield components in the harshest upstream, midstream, and downstream conditions—delivering a chrome free, wear resistant, and corrosion tough surface that extends component life, reduces failure, and lowers total cost of ownership.

We commercialize this technology through local Channel Partners—licensees or joint venture partners—whom we train, supply, and enable to build sustainable coating capacity in their own markets. Operators and OEMs benefit from standardized performance, while partners unlock a scalable, high margin coatings business backed by exclusive supply and a proven enablement program.