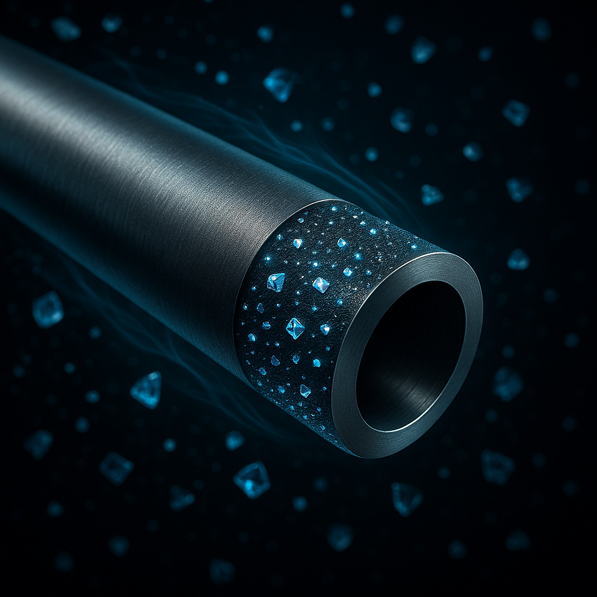

Military & Defense Coatings — Electroless Nickel NanoDiamond for MissionCritical Reliability

Defense assets operate where failure is not an option: saltladen maritime air, sand and dust, thermal cycling, shock and vibration, mixedmedia corrosion, and high load interfaces. Metal Diamond’s Electroless Nickel NanoDiamond coating (ENND) is engineered to protect missioncritical components with a chromefree, wearresistant, lowfriction, corrosiontough surface that supports readiness, maintainability, and lifecycle cost control across land systems, naval platforms, aerospace/space, weapons systems, and UAVs/autonomous systems.

We commercialize through Channel Partners—licensed or jointventure coating providers—so primes, Tier1/Tier2 suppliers, depots, and MROs can access standardized quality locally, with line setup, training/certification, and assured materials supply.